Flow quantity: 1 t/h - 50 t/h

Yang cheng: 1.6 bar to 6.5 bar

Sealing machine sealing: double machine

Inlet pressure: 100 kpa or less (one bar)

Noise sound: within 1 meter or less 85 db (A)

ABB IP55 electric machine: 380 v

Transfer rate: 2900 RPM

Material quality: 304-316 l

Surface treatment: the fine cars, impeller and pump head sealing plate sandblasting another optional mirror

Application scope: dairy products, beer, pure water, beverage, pharmaceutical, wine and other health fluid conveying

This series of pump belongs to the idler diversion centrifugal suction pump. Induced by wheel, can effectively improve the pump cavitation resistance, ensure the pump at work can provide pressure stably and reliably, and can be in the negative pressure 0.09 Mpa pressure, pump in liquid in the vacuum can.

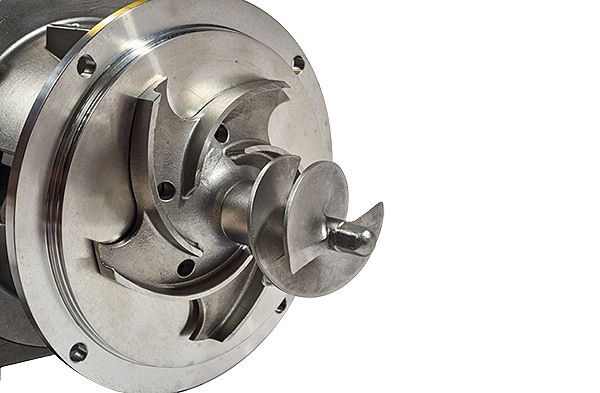

1, ZAF series negative pressure pump is mainly composed of pump head, photosensitive plate, impeller, guide wheel, mechanical seal, motor parts, such as group. Design using smooth excessive, rigid structure, thick wall design. Each part respectively by the bolt connection. Under the floor there are four can be arbitrary adjust the weight from foot to foot, easy to install, without the installation of fixed base. When installation, according to different needs to outlet pipe installation into vertical direction or horizontal direction.

2, negative pressure pump mechanical seal USES the import high quality graphite and silicon carbide custom, greatly improving the wear resistance and the embellish prolonged the service life. When the pump head, the impeller made by whole precision casting, all parts after surface treatment. When installed by the special jig ensure dimension clearance.

3, shaft seal adopts open structure, even if there is a small amount of leakage, can detect in a timely manner. Even if a short period of time was found at the end of the night will not overflow to the motor, thus ensuring the service life of the motor.

4, this series of pumps are especially suitable for the vacuum negative pressure.

5, open design double machine impeller sealing structure, remove the convenience of low noise, high efficiency, the gentle and soft materials handling under the food hygienic requirements and to ensure the products of the original flavor and high quality characteristics.